So You Want to Build an Acrylic Sandwitch Frame

Over the years, a number of customers have asked about buying acrylic and making their own sandwich frames. There are a number of considerations that you will need to keep in mind to build an acrylic sandwich frame successfully. I don't sell acrylic for sandwich frames. I only carry .118" acrylic and for many of your frames you will need .25" or .375" thick acrylic for the back.

High Quality Or As Cheap As Possible? Some of you just want to put together an acrylic frame as cheap as possible without regard to the overall esthetics. Others want a high quality professional looking product. This page is geared towards those wanting a professional looking product. Web searches can be done on any of these subjects. I won't provide actual links as pages and videos come and go. You can search for these on your own.

What Acrylic to Use? There are a lot of acrylic and Styrene products available online and through your home centers. Framing Grade Acrylic should be used. It is manufactured to higher standards than regular acrylic and will have fewer defects. Styrene isn't recommended.

Framing Grade Acylic comes in Premium Clear (FF3), Non-Glare (P99), UV Protective (OP3) and UV/NG (OP3P99). OP3 and OP3P99 has a 99% UV Protective rating.

Some folk want to use a higher grade for both the front and back of the frame. This isn't necessary. Use the higher grade on the front and Premium Clear on the back. Since the back is facing the wall, there is no need for Non-Glare or UV Protective properties on the back.

What Thickness of Acrylic to Use? Framing Grade Acrylic comes in a variety of Thicknesses with .090" and .118" being the most prevalant. For smaller prints (under about 12" x 16"), .118" can be used on both the front and back. For larger prints, a thicker back is needed to keep the acrylic from flexing or bowing. For most larger prints 1/4" is fine, with some larger prints needing 3/8" or thicker. Thicker acrylic is more difficult to find. A sign maker might be your best bet.

The pieces must be the identical size. This goes without saying. When you line up the front and back pieces, the must be exactly the same size. Anything else is distracting.

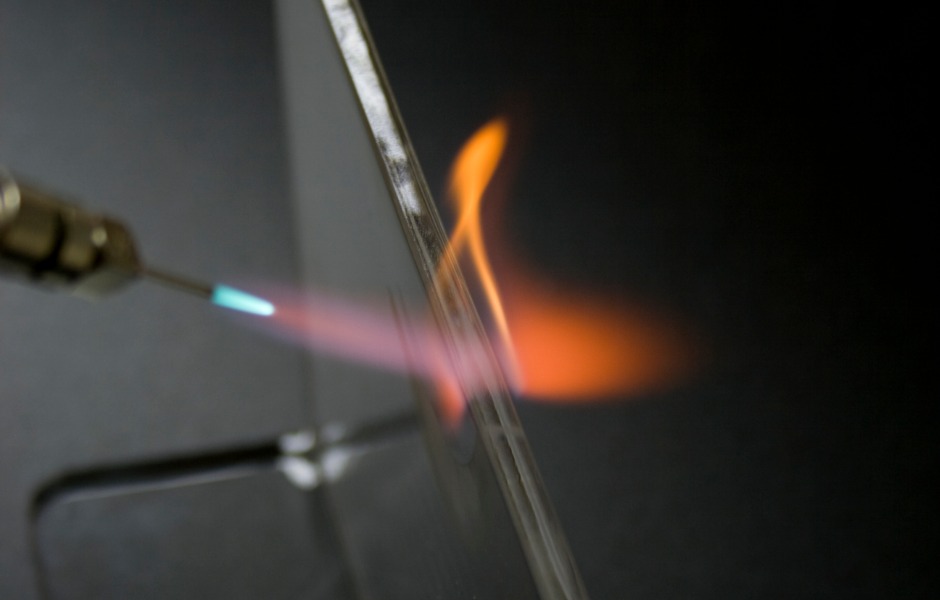

Polishing The Edges? The edges can be polished using one of two methods; Wet Sanding and Buffing an Flame Polishing. The image at the right show Flame Polishing. When doing Flame Polishing, pertinent safety precautions need top be observed.

Wet Sanding and Buffing is more tedious but safer.

There are many videos available for both methods.

Installation. This is one the most time consuming parts and if done incorrectly will leave you with holes in your wall. You should view some of the many videos available.

Bottom Line If you want a professional looking acrylic frame, you need to have the tools required, access to acrylic of the proper thickness and have the skills needed for this. If you are lacking any skills, equipment or materials required, you should consider buying an acrylic frame rather than trying to build one.